Understanding Warp Knitting: A Technical Perspective

Warp knitting is an essential method in the world of textiles that involves a simultaneous interlocking of yarns moving lengthwise. Unlike weft knitting, which stitches loops horizontally, warp knitting forms vertical loops, creating robust and stretchy fabrics.

This technique has deep historical roots, evolving from hand-knitting practices to modern mechanized processes that began revolutionizing fabric production during the Industrial Revolution.

The Machinery Behind Warp Knitting

Central to warp knitting are specialized machines like tricot and raschel models. Tricot machines excel at producing lightweight and fine-textured fabrics, while raschel machines craft more complex and heavier designs, including intricate laces and meshes.

These machines consist of needles, guide bars, and sinkers functioning together to loop yarns into structured fabric. Technological advancements have greatly enhanced their speed, precision, and versatility, allowing for continuous innovation in textile manufacturing.

The Process of Warp Knitting

Embarking on warp knitting begins with meticulous yarn preparation and threading through the machine's guide bars. The needle action then interloops yarns vertically, forming stable stitches reinforced by subsequent rows. This process ensures consistent texture and durability across the produced fabric.

Characteristics of Warp Knitted Fabrics

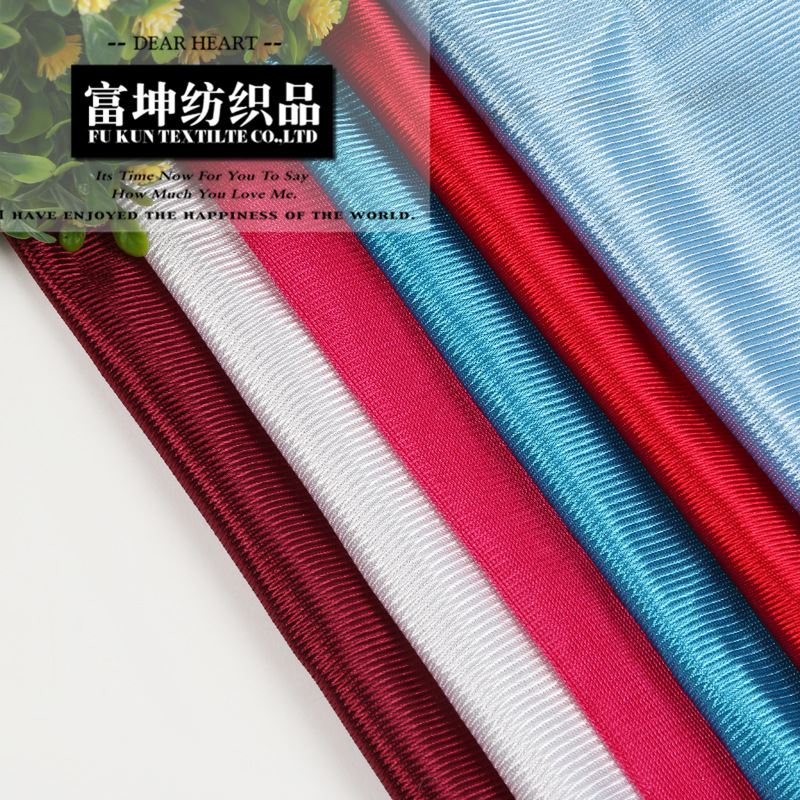

Warp knitted fabrics stand out due to their remarkable elasticity and strength, key traits derived from their unique structure. These fabrics offer excellent dimensional stability, maintaining shape even after stretching or compression. Their surface can vary widely, presenting textures from smooth and sleek to intricately patterned and textured.

Types of Warp Knitted Fabrics

Diverse variants of warp knitted fabrics cater to various applications. Tricot fabrics are known for their softness and flexibility, making them ideal for intimate apparel and comfortable clothing. Raschel lace adds elegance and complexity to fashion items, while net and mesh fabrics provide breathable solutions for sportswear and other practical uses.

Advantages Over Other Fabrics

The distinct features of warp knitted fabrics bring several practical benefits. They boast exceptional durability and longevity compared to their woven counterparts. Their adaptability suits a wide range of applications, not limited to fashion but extending to technical fields such as automotive interiors and medical textiles. Plus, their maintenance is relatively straightforward, often requiring less frequent washing and special care.

Applications in Various Industries

The impact of warp knitted fabrics spans multiple industries. In the realm of fashion and apparel, these fabrics support creative expression while ensuring comfort and fit. Sportswear benefits immensely from their breathability and resilience. Even beyond traditional uses, warp knit textiles contribute significantly to technical purposes, offering tailored solutions for automotive, medical, and industrial needs.

Innovations and Future Trends

Ongoing innovations continue to reshape warp knitted fabrics. Emphasis on sustainable materials drives eco-friendly production practices. The integration of smart textiles enhances functionality with technology, enabling features like temperature regulation and health monitoring. Additionally, customization through 3D printing opens new avenues for bespoke designs and rapid prototyping.

Expert Tips for Choosing Warp Knitted Fabrics

Selecting the right warp knitted fabric requires understanding its intended use. Match the fabric properties with performance requirements, considering factors like stretch, durability, and texture. Quality assessment should focus on uniformity and construction integrity, while cost considerations must balance budget constraints against desired attributes.

Real-World Examples and Case Studies

Numerous industry leaders leverage warp knitted fabrics to create innovative products. Brands within fashion and activewear sectors showcase success via consumer-focused designs that combine style with practicality. Positive feedback underscores user satisfaction, validating the choice of warp knits in diverse product lines.

Practical Advice for DIY Enthusiasts

Working with warp knitted fabrics can be rewarding yet challenging. Use sharp, high-quality sewing tools to handle delicate structures without causing damage. Be aware of common pitfalls, like excessive stretching during cutting, and employ stabilizing methods to maintain fabric integrity. Recommended tools include ballpoint needles and serrated scissors to ensure clean cuts and consistent seams.